Posted by Modulus Arms on 27th Nov 2021

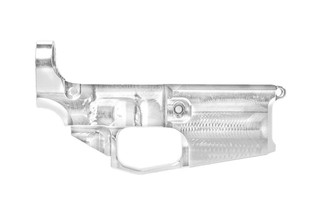

Why Buy A Raw 80% Lower?

A raw 80 percent lower is exactly what it sounds like - an 80 lower that has not had any treatment for its surface’s finish which means you get a lower receiver without any color or coating, just bare untreated aluminum. For people building their ARs as a personal project, it’s more common for builders to choose a color like black, flat dark earth or olive drab green… raw, shiny aluminum typically screams “ghost gun!” So some might understandably want to avoid that. Others might not care and all the more power to them.

There are actually a couple of practical reasons for buying raw 80 lowers though. First, it gives builders the option to choose their own colors used for the finish. Sometimes, the standard black, FDE and ODG can get boring so some might want to take the paint colors into their own hands. Second, raw lowers are typically a little bit cheaper than lowers that have been anodized or applied with a cerakote finish. So if you really need to save every dollar and like painting projects then a raw 80 lower is perfect for you. Below we've included a few different methods builders might take to go about painting their raw lower receivers.

Spray Paint

Spray painting is typically what comes to mind for most people when it comes to painting uneven surfaces. Brands like Rust-Oleum, Behr and Aluma-Hyde are just a few of the staple spray paint brands for firearms. Although the coats are durable for spray paint, no brand will be able to surmount the fact that spray paint is not a permanent finish and will wear off a lot more quickly than proper coatings. The worn, rugged look as the spray paint wears off, however, is a quite popular aesthetic to many people.

“Rattle canning”

Rattle canning is simply the verb we use to refer to someone painting with spray paint because of the need to often shake up the bottle to properly mix the aerosol and paint together. Rattle canned firearms are most distinctive with rattlesnake-like scale patterns and gradient blurs of contrasting colors. Sometimes people will use a mixture of different foliage, wired mesh to paint over a gun. Rattle canning is a cost-effective means of having a raw 80 lower that blends naturally with the surroundings. For multi-color coats of spray paint, it is recommended to use the darkest layer of paint before moving onto lighter colors. Once the primary coat of darker color(s) is on the raw 80 lower, you can switch to making sharper lines as needed with the contrasting colors. As we just mentioned, these lines can be broken up with fabrics of mesh to form the scale-like pattern.

Duracoat

Duracoat is a tough, self-lubricating two part finish that uses a base color and a hardening agent. Once mixed, the coat is ready to be applied via aerosol after degreasing your raw 80 lower. Duracoat is a very protective finish that will ensure your firearm won’t rust in even salt-water environments - it's capable of withstanding up to 600 degrees Fahrenheit, enough to hold its own on the surface of a semi automatic barrel under normal operations. If you think you’ll be exceeding temperatures of 1800 degrees Fahrenheit from mag dumping or from having the magical third hole on your lower, then feel free to try out DuraHeat.

Cerakote

Cerakote has served as the modern standard for 80 lower finishes. No longer must users depend on blued-steel bathed with cosmoline to keep corrosion at bay. Cerakote comes in all the colors one can want for their firearm, even the type of colors that would earn your gats the top post of /r/PlebianAR... Cerakote is a blend of ceramic and polymer that can be applied to any plastic, wooden, or metal surface. This is a process that produces a clean, waterproof finish. It begins with the degreasing of the raw 80 lower and is then sand blasted with garnet sand to wipe off any remaining debris and oil. The cerakote coating is applied on the surface with an HVLP (High Volume Low Pressures) spray gun and then placed in an oven to cure. Metal parts such as the raw aluminum lower itself has the cerakote finish baked into the surface at 250 Fahrenheits while any polymer furniture and other plastic components are allowed to cook for 150 to 180 Fahrenheits.

Cerakote vs Spray paint

Cerakote is incomparable to spray paint when it comes to durability, waterproofness, and friction. While spray paint adds 3-5 millimeters of thickness, a proper cerakote finish on a raw 80 lower should not add more than 1 millimeter of thickness. The cerakote finish has a smaller friction coefficient than spray paint and will help your firearm run smoothly. Cerakote also offers your 80 lower and other treated components more impact resistance to fracturing and deformation. While duracoat also provides similar protection, it is a permanent finish and cannot be removed. Unlike duracoat and spray paint, cerakote finishes are to last a lifetime and can be removed with a session of media blasting if you ever want to go in a different direction with the color scheme. While duracoat requires up to 5 or 6 weeks to finish completely curing, cerakote only needs less than a week.

How much does cerakote and duracoat cost?

The primary disadvantage to a coating that does it all is the cost. Cerakote jobs can cost a pretty penny, with the whole firearm in matching colors running you hundreds of dollars. Multicam patterns requiring various cerakote colors can look sexy but be prepared to spend. It is a task that often has to be done at a professional shop and is very easy to make mistakes for an amateur. Duracoat on the other hand can be applied from the comfort of your ventilated garage or shed for less than $40 excluding the cost of a spray gun.

Can you cerakote optics?

If you intend to match your entire firearm with accessories included, it is worth noting that some sensitive optics can’t withstand the hot cerakote baking sessions in the oven and will not function properly. If this is a concern for you, options for wrapping your scopes, red dots, and NVGs to match with your firearm are available.To have the protective finish of cerakote while still wanting a specific pattern design, you could always have a base layer of anodized paint and cerakote over that to match with your optics or any other non-cerakoted accessories.

Get your raw 80 lower from Modulus Arms today

Have you found a painting method that works for you? Maybe you don't even care about the color and just want to build a budget AR to stick it to the man. We're all for that. Order a raw 80 lower from us today and get started with your new build. Our lowers all come with lifetime warranty and go well with our Router Jig Extreme which can help you quickly complete an 80% lower in record time!